Activated carbon adsorption and desorption

Overview: This system consists of adsorption, desorption, condensation and recovery units. The technical principle is that the organic solvent waste gas is subjected to pre-treatment equipment to remove particles and cool down, and then enters the adsorption desorption device for purification before meeting emission standards; After saturation of activated carbon adsorption, it enters steam (vacuum) desorption through system switching. After desorption, the solvent vapor and water vapor are condensed and enter the separation system for recovery in the form of a single solvent or mixed liquid.

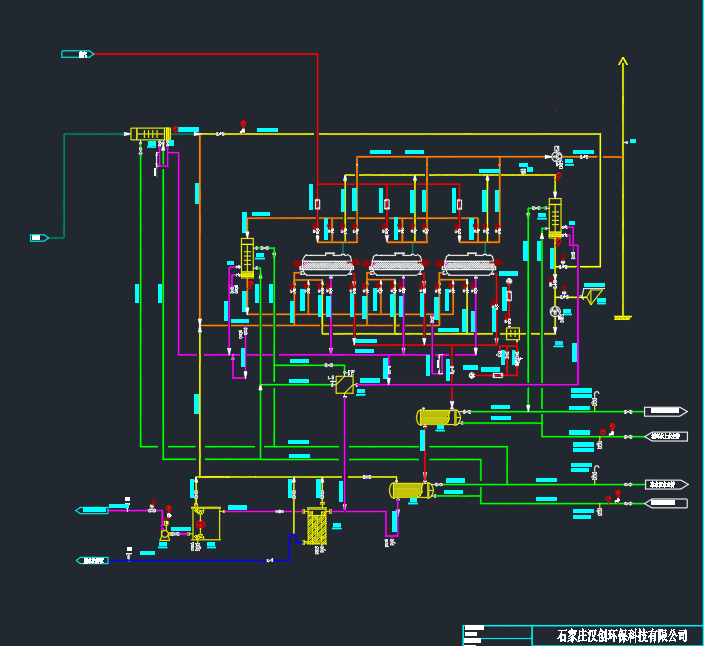

Technological process

Stage A: Activated carbon is used to fully adsorb the molecules of organic components in the exhaust gas, and the adsorption stops when it reaches a certain saturation level.

Stage B: At the beginning, saturated low-pressure steam is used to heat or vacuum analyze activated carbon, activating and gasifying the adsorbed organic components to desorb and escape from the activated carbon. Activated carbon with restored activity can re adsorb gas molecules of organic components.

Stage C: Condense the desorbed organic gas to liquefy it, and then further process it.

Adsorption and desorption process flowchart

Technical advantages

1. The system adopts a ring design, sharing a set of pipeline system, and adsorption and desorption are carried out simultaneously to achieve continuous operation.

2. Adopting a PLC system, all action switching during operation can be automatically completed, achieving system automation.

3. The use of activated carbon temperature swing adsorption technology has high treatment efficiency and is suitable for the purification and recovery of one or more organic solvent waste gases.

4. The activated carbon price of this system is low, the adsorbent cost and system engineering cost are significantly reduced, the environmental and economic benefits are significant, and the investment payback period is short.

5. Especially suitable for VOCs with low concentration, high air volume, or high concentration intermittent emissions and strict emission standards that are difficult to meet using other retrospective methods.

Scope of application

Suitable for purifying organic waste gases with low to medium air volume and low to medium concentration. The organic solvents that can be processed include benzene, alcohols, alkanes, ketones, esters, aldehydes, ethers, and their mixtures. It can be applied in industries such as pharmaceuticals, petrochemicals, furniture, coal chemical, synthetic leather, printing and dyeing, coatings, rubber, plastics, footwear, electronics, chemical fibers, brewing, etc.

Physical picture of Hanchuang Engineering case: