Carbon fiber adsorption

Overview: The system device is the same as the activated carbon particle system, but the difference is that activated carbon fiber (PAC) is a new and efficient adsorbent. As this is a typical microporous carbon (MPAC), it is a combination of ultrafine particles, irregular surface structures, and narrow spaces. The diameter ranges from 10 μ m to 30 μ m, and the gaps directly open on the surface of the fibers. The ultrafine particles combine together in various ways to form enriched nano spaces. The diffusion path of the adsorbate to the adsorption site is shorter than that of activated carbon, with greater driving force and concentrated pore size distribution. This is the main reason why ACF has a faster elution rate and higher adsorption efficiency than GAC.

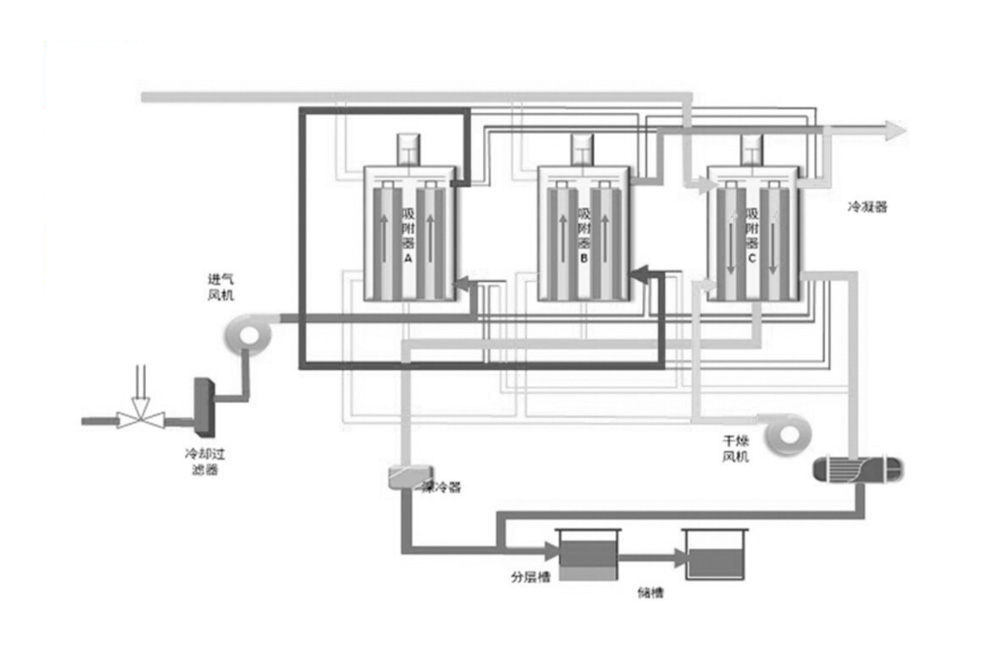

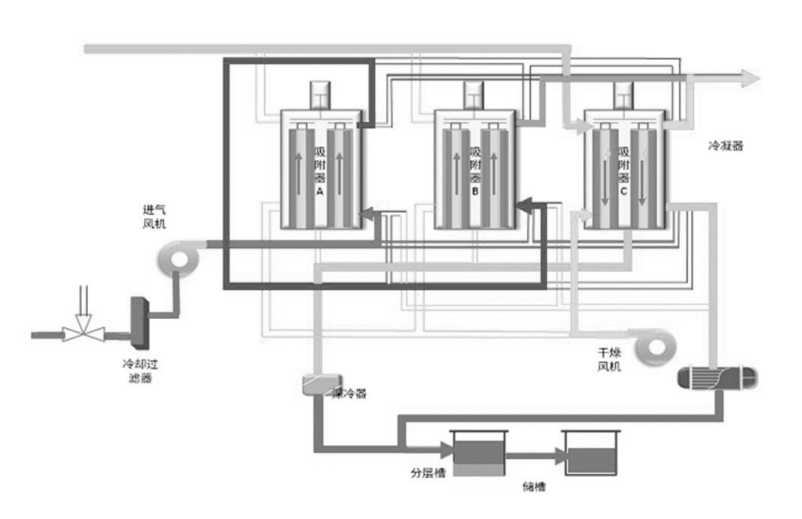

Technological process

The system consists of a fan, gas filter, activated carbon fiber adsorption tower, condenser, and separator. Carbon fiber regeneration also requires steam or nitrogen gas. During desorption, water vapor is used to achieve the desorption of organic gases from carbon fibers. The desorbed solvent and water vapor are condensed in a condenser and separated by a separator to obtain pure solvent. The activated carbon fibers in the detached filter cartridge must be dried with hot air before they can be reused.

工艺流程图

Technical advantages

1. The stability of the solvent during recycling is good, with minimal decomposition, which can remove, recycle, and purify solvents from VOCs in industrial manufacturing processes. This is a very economical solution for controlling emissions.

2. Widely applicable, mainly used for the treatment of low concentration, high gas volatile organic compounds, and can also be applied to polymeric monomers and high boiling point solvents.

3. The organic solvent recovery rate is high, and through reasonable design and adjustment of switching time, the solvent recovery rate can be above 95%.

4. The device has a small volume, is easy to operate and maintain, and has high safety. The adsorption heat of activated carbon fiber is very small and easy to dissipate, which will not cause excessive local temperature. It has low energy consumption, mature technology, high removal rate, and thorough purification.

Scope of application

Suitable for the purification and recovery of organic waste gases with large solvent content and high solvent value. The organic solvents that can be processed include benzene, alcohols, alkanes, ketones, esters, aldehydes, ethers, and their mixtures. It can be applied to industries such as petroleum, pharmaceuticals, chemicals, agrochemicals, synthetic fibers, rubber, electronics, printing, coating, spraying, and leather making.

Physical case: